Production Engineering problems

- 1. The shear velocity is the velocity of

Options- A. tool relative to the workpiece

- B. chip relative to the tool

- C. tool along the tool face

- D. none of these Discuss

Correct Answer: none of these

- 2. In drilling bakellite and fibrous plastics, the point angle of a drill is

Options- A. 90°

- B. 118°

- C. 135°

- D. 150° Discuss

Correct Answer: 90°

- 3. The vector sum of cutting velocity and chip velocity is __________ shear velocity.

Options- A. equal to

- B. less than

- C. more than Discuss

Correct Answer: equal to

- 4. The angle between the lathe centres is

Options- A. 30°

- B. 45°

- C. 60°

- D. 90° Also asked in: Bank Exams

Correct Answer: 60°

- 5. The rate of removing metal is __________ by increasing the depth of cut.

Options- A. decreased

- B. increased Discuss

Correct Answer: increased

- 6. A grinding wheel is said to be of __________ if the abrasive grains can be easily dislodged.

Options- A. soft grade

- B. medium grade

- C. hard grade Discuss

Correct Answer: soft grade

- 7. In a shaper, the metal is removed during

Options- A. forward stroke

- B. return stroke

- C. both the forward and return strokes

- D. neither the forward nor the return stroke Discuss

Correct Answer: forward stroke

- 8. Which of the following statement is correct about EDM machining?

Options- A. It can machine hardest materials.

- B. It produces high degree of surface finish.

- C. The tool and work are never in contact with each other.

- D. all of these Discuss

Correct Answer: all of these

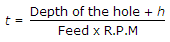

- 9. The time (in minutes) for a drilling a hole is given by

where h is the

Options- A. length of the drill

- B. drill diameter

- C. flute length of the drill

- D. cone height of the drill Discuss

Correct Answer: cone height of the drill

- 10. In __________ operation, the cutting force is maximum when the tooth begins its cut and reduces it to minimum when the tooth leaves the work.

Options- A. up milling

- B. down milling

- C. face milling

- D. end milling Discuss

Correct Answer: down milling

More in Mechanical Engineering:

Programming

Copyright ©CuriousTab. All rights reserved.