Discussion

Home ‣ Mechanical Engineering ‣ Production Engineering See What Others Are Saying!

- Question

If the diameter of the hole is subject to considerable variation, then for locating in jigs and fixtures, the pressure type of locator used is

Options- A. conical locator

- B. cylindrical locator

- C. diamond pin locator

- D. vee locator

- Correct Answer

- conical locator

- 1. If a number of forces are acting at a point, their resultant is given by

Options- A. (?V)2 + (?H)2

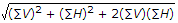

- B.

- C. (?V)2 +(?H)2 +2(?V)(?H)

- D.

Discuss

Discuss

- 2. The wet bulb depression indicates __________ humidity of the air.

Options- A. absolute

- B. relative

- C. specific Discuss

- 3. The work ratio of simple gas turbine cycle depends upon

Options- A. maximum cycle temperature

- B. minimum cycle temperature

- C. pressure ratio

- D. all of these Discuss

- 4. Nimonic contains __________ percentage of nickel as that of Inconel.

Options- A. same

- B. less

- C. more Discuss

- 5. The discharge through an external mouthpiece is given by (where a = Cross-sectional area of the mouthpiece, and H = Height of liquid above the mouthpiece)

Options- A. 0.855 a2gH

- B. 1.855 aH2g

- C. 1.585 a2gH

- D. 5.85 aH2g Discuss

- 6. The factor considered for evaluation of machinability is

Options- A. cutting forces and power consumption

- B. tool life

- C. type of chips and shear angle

- D. all of these Discuss

- 7. In an impulse turbine, the jet of water impinges on the bucket with a low velocity and after flowing over the vanes, leaves with a high velocity.

Options- A. True

- B. False Discuss

- 8. The starting system includes

Options- A. a battery, a starter, and an ignition switch

- B. a battery, a distributor, and an ignition switch

- C. a battery, a starter, and a distributor

- D. a distributor, a starter, and an ignition switch Discuss

- 9. The ratio of shear modulus to the modulus of elasticity for a Poisson's ratio of 0.4 will be

Options- A. 5/7

- B. 7/5

- C. 5/14

- D. 14/5 Discuss

- 10. Brass is an alloy of

Options- A. copper and zinc

- B. copper and tin

- C. copper, tin and zinc

- D. none of these Discuss

More questions

Correct Answer:

Correct Answer: relative

Correct Answer: all of these

Correct Answer: same

Correct Answer: 0.855 a2gH

Correct Answer: all of these

Correct Answer: False

Correct Answer: a battery, a starter, and an ignition switch

Correct Answer: 5/14

Correct Answer: copper and zinc

Comments

There are no comments.More in Mechanical Engineering:

Programming

Copyright ©CuriousTab. All rights reserved.