Discussion

Home ‣ Mechanical Engineering ‣ Production Engineering See What Others Are Saying!

- Question

Segmental chips are formed during machining

Options- A. mild steel

- B. cast iron

- C. high speed steel

- D. high carbon steel

- Correct Answer

- cast iron

- 1. Willian's law states that the steam consumption per hour provided with a throttled governor is proportional to (where I.P. = Indicated power)

Options- A.

- B.

- C. I.P.

- D. (I.P.)2 Discuss

- 2. The velocity ratio in case of an inclined plane inclined at angle ? to the horizontal and weight being pulled up the inclined plane by vertical effort is

Options- A. sin ?

- B. cos ?

- C. tan ?

- D. cosec ? Discuss

- 3. Which of the following does not relate to a compression ignition engine?

Options- A. Fuel pump

- B. Fuel injector

- C. Governor

- D. Carburettor Discuss

- 4. Which of the following pump is successfully used for lifting water to the turbines?

Options- A. Centrifugal pump

- B. Reciprocating pump

- C. Jet pump

- D. Air lift pump Discuss

- 5. The by-pass factor (B. P. F.) in case of sensible heating of air is (Where td1 = Dry bulb temperature of air entering the heating coil, td2 = Dry bulb temperature of air leaving the heating coil, and td3 = Dry bulb temperature of heating coil)

Options- A.

- B.

- C.

- D.

Discuss

Discuss

- 6. The force exerted by a jet of water impinging normally on a plate which due to the impact of jet, moves in the direction of jet with a velocity v is

Options- A.

- B.

- C.

- D.

Discuss

Discuss

- 7. The centrifugal pump preferred for a specific speed between 80 to 160 r.p.m. is

Options- A. slow speed with radial flow at outlet

- B. medium speed with radial flow at outlet

- C. high speed with radial flow at outlet

- D. high speed with mixed flow at outlet Discuss

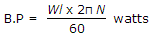

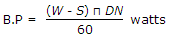

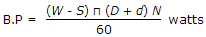

- 8. The brake power (B.P.) of the engine is given by (where W = Brake load or dead load in newtons, l = Length of arm in metres, N = Speed of engine in r.p.m., S - Spring balance reading in newtons, D = Dia. of brake drum in metres, and d = Dia. of rope in metres)

Options- A.

- B.

- C.

- D. all of these Discuss

- 9. Moment of inertia of a circular section about an axis perpendicular to the section is

Options- A. ?d3/16

- B. ?d3/32

- C. ?d4/32

- D. ?d4/64 Discuss

- 10. When a gas is heated at constant pressure

Options- A. its temperature will increase

- B. its volume will increase

- C. both temperature and volume will increase

- D. neither temperature not volume will increase Discuss

More questions

Correct Answer: I.P.

Correct Answer: sin ?

Correct Answer: Carburettor

Correct Answer: Jet pump

Correct Answer:

Correct Answer:

Correct Answer: high speed with mixed flow at outlet

Correct Answer: all of these

Correct Answer: ?d4/32

Correct Answer: both temperature and volume will increase

Comments

There are no comments.More in Mechanical Engineering:

Programming

Copyright ©CuriousTab. All rights reserved.